Drying technology

Practical Action

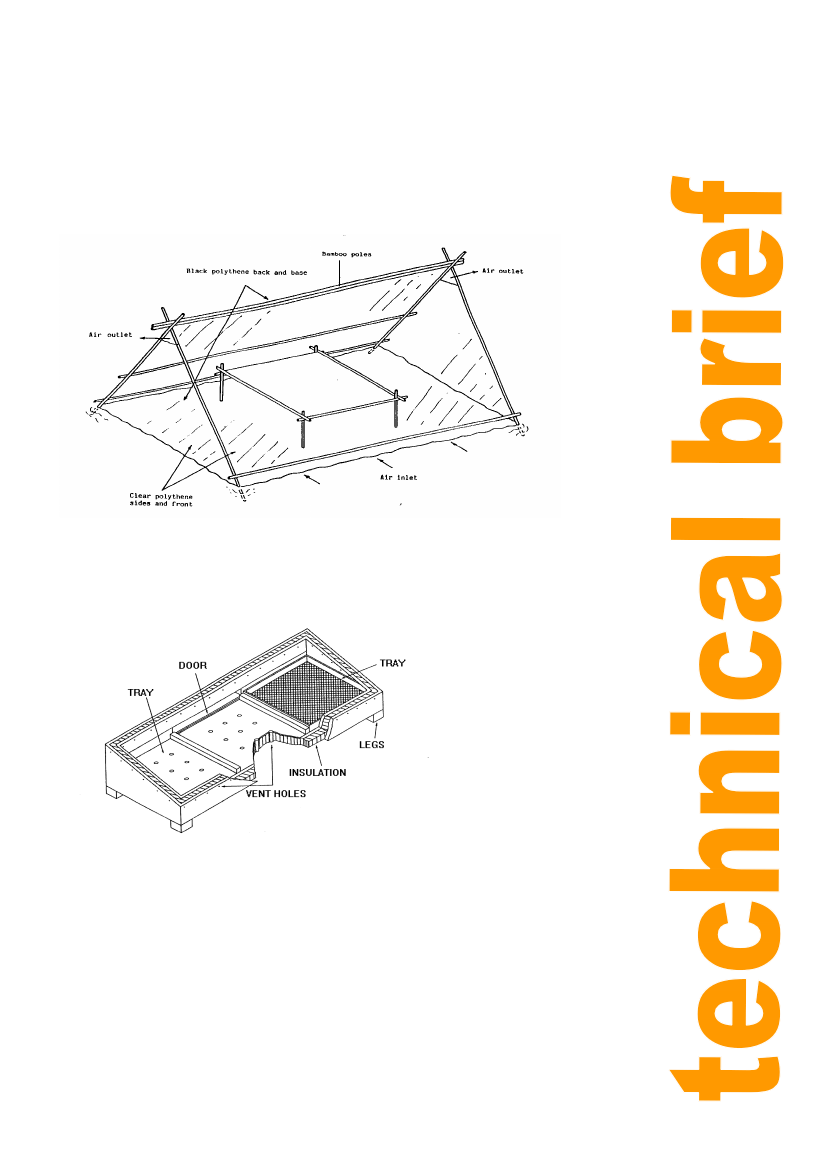

Tent solar dryers, as shown in Figure 1, are cheap and simple to build and consist of a frame of

wood poles covered with plastic sheet. Black plastic should be used on the wall facing away from

the sun. The food to be dried is placed on a rack above the ground. Tent dryers provide protection

against rain, insects and dust and, in the case of fish for example, can reduce drying times by

25%. Tent dryers can also be taken down and stored when not in use. They have the

disadvantage of being easily damaged by strong winds

Figure 1: Typical tent solar dryer

The Brace solar dryer as shown

in Figure 2 has been widely

used for small scale food

drying. It consists of a wooden

box with a hinged transparent

lid. The inside is painted black

and the food supported on a

mesh tray above the dryer floor.

Air flows into the chamber

through holes in the front and

exits from vents at the top of

the back wall. Brace type dryers

achieve higher temperatures,

and thus shorter drying times,

than tent dryers.

Figure 2: Typical brace type dryer

A further design of solar dryer uses of a separate solar collector which supplies heated air to a

chamber containing trays of food. This is known as an indirect solar dryer and a typical design is

shown in Fig

3. Dryers of this type have several advantages over direct dryers which include:

the food is not exposed to the direct rays of the sun which reduces the loss of colour and

vitamins.

2